The shafts on both sides of the cradle are supported by bearings, Frame

is fasten under the ground by expansion screws (HONTA Supply

expansion screws.). Then adjust to the level by adjusting bolt.

Rotation shaft: Adopt to design of 2pcs bracket of steel

structure to connect single bow, energy saving and low noise.

Shafts are mounted into high precision bearings, which are

grease lubricated through points joined outside, to allow lubrication even

if machine is running, and are placed on cast iron removable housings.

The motion is transmitted to the shaft by a transversal transmission

shaft via pulleys and toothed belts.

Each shaft is complete with pulley (made of high resistance aluminium

alloy), The grooves of the guide wheel are coated with ceramics

(Sometimes adopt the whole ceramic zirconia pulley.)

Pulleys rotate on high performance, grease lubricated bearings ,

are fitted on outer flanges, as protection against dynamic wind and

are complete with pin made of titanium.

AC MAIN MOTOR: connected through universal joint to the above

transversal transmission shaft; then transmit to bow belt. Through

AC45kw motor transmit to haul-off capstans. Adjust the rotate

speed of main motor and the speed difference of haul-off capstans

to reach the pitch size of stranding wire, complete realize the

control and adjust of electronic pitch.

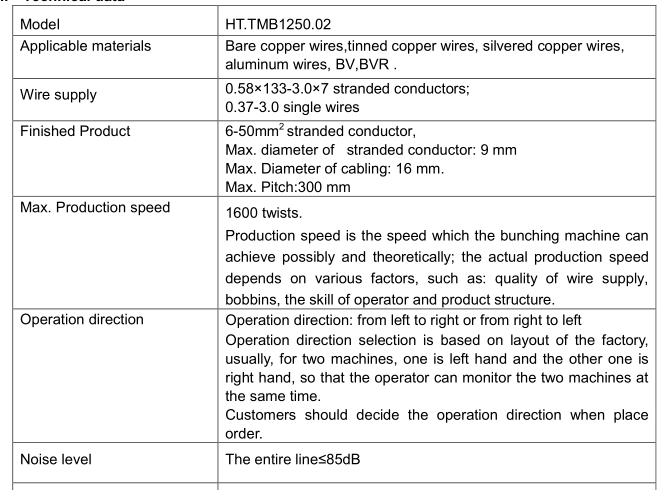

Technical Specification :